|

|

Elizabeth uses a ruler to determine how far apart the tines are in her combs. This information was recorded on tags, attached to the comb, so once they were again wrapped in their protective materials, she could tell what size they are. This is one item in our collection that stays in storage, because of all those sharp points. This selection represents part of her collection.

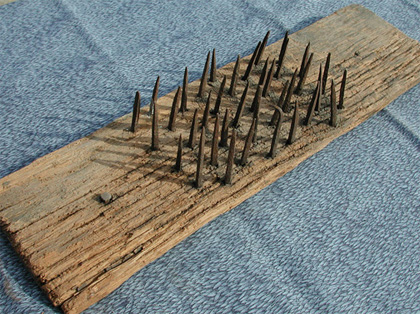

Flax combs are called different names for different reasons, perhaps area of origin. Some names encountered are flax hackle, heckle, hatchel, or hetchel. These names essentially describe a heavy board containing rows of teeth or spikes used for combing the flax fibers.

Usually three combs were used going from a coarse to a fine toothed comb. A coarse comb may have tines one-inch apart while a fine-tooth comb may have tines set almost a quarter inch apart.

|

1770 Flax Comb

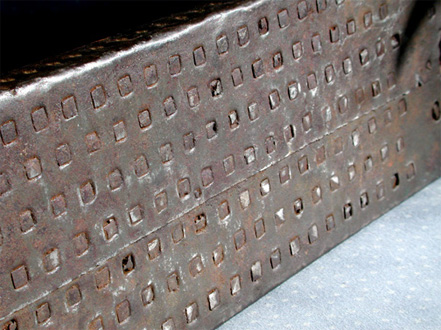

The CHGM - 1770 Flax Comb is probably our "best" antique flax comb. If the date is to be believed--and we have no reason not to--this flax comb is about 230 years old. It is constructed of some of the finest square nails of any comb we have. These nails were made by someone with exceptional blacksmith ability or by machine. The CHGM were most likely initials for the giver and the receiver of the comb. Textile tools were frequently gifts to future brides.

|

Primitive Flax Comb

Compare the square nails on this comb to the comb just above it. To insert the nails into the board, the maker probably first drilled small pilot holes at the points he wished to place a nail. He would then heat the nail to red hot and plunge it into green wood burning its path as it went and forming a perfect fit. Timing is everything. The nail must be cooled as soon as it is seated to stop burning the wood. When the wood dries it will shrink about the nail forming a fit as tight as can be achieved with modern glues.

|

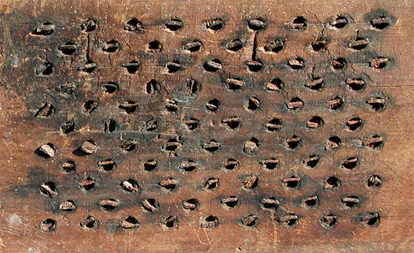

Back Side of Primitive Flax Comb

Clues in the back side of this flax comb reveal its construction. To begin with, the maker used an awl to scribe lines across a board into which the nails will be driven. The comb shows alternate rows of four and five nails staggered for most effectiveness as a comb.

The maker, was probably an amateur blacksmith. This is evident in the construction of the square nails in its construction. (Blacksmiths who often make hundreds or thousands of nails develop a routine of forming not only nails of consistent length and shape. Additionally, they will develop a habit of forming the nail head with exactly the same number and angle of swings of their mallet in forming each head.) The comb above shows quite a variation in nail heads.

Without knowing the conditions under which the comb was created, the person who made it should be given a lot of credit as the nails could have been formed from pieces of old recycled iron such as horseshoes or worn wagon wheel rims.

Knowing nail heads will be exposed, some smiths go to extremes to make them look nice and often decorative. Examples of these are presented farther down on this page.

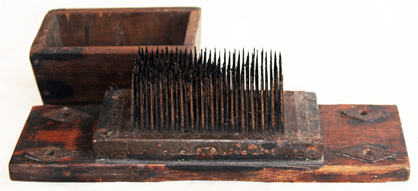

Below is a comb whose tines are made from round stock. The wooden box was used to protect the tines from becoming bent or broken (not to mention puncturing human parts that got too close). Some boxes will contain a handful of flax tow which prevents rust from forming on the tines.

|

Flax comb tines come in various footprints. While most are tines are set rectangularly, some were set in a circular pattern.

|

This possibly Swedish comb was used without a bench. One opening was for the toe of your shoe and the other was for your hand. The flax was pulled though the tines in a upward motion. Since you are bent over to operate this flax comb, it would have been indeed a hard days work.

|

In use, flax combs were arranged on a bench from coarse to fine. The comb above could be considered a medium tooth comb because of the density of tines.

|

This is the only comb we have seen with a handle. Most combs have a hole on either side of the tines to fasten them down to a surface. The box that protects the tines has a hand forged hooks to hold it in place.

|

The bottoms of combs can tell a lot about the item. image above shows a diagonal pattern of round tines. It is easy to see that the tines were spikes and probably never had nail heads. The comb below shows a similar pattern but were driven through a sheathing of tin.

|

The backside of the 1770 comb below shows square nails driven into tin but in an extremely order.

|

Most combs were secured to a bench when they were used. The image below shows a very nice reinforced hole which could easily be dropped over a peg on the workbench to hold the comb fast when the flax was pulled though the tines.

|

Flax Comb Hold-down

A number of ways are seen which secure the comb so it doesn't move when flax is being drawn through it. Some combs show a simple hole in the base while others have metal "industrial strength" anchor points shown above.

|

If you look closely you can see the attractive punching in the tin that secures the comb to its raised base.

|

Flax Comb With Cover

The flax comb above came with a wood cover. Also, note that the base has a hole on each corner of its base which will secure the comb better than a single hole in the center of the base.

|

|

Updated June 4, 2009

|